Machining the aluminum plates

Finally the machine is in a shape that its possible to start making the aluminum plates bought from kauppa.al-men.fi to be replacing the plywood plates.

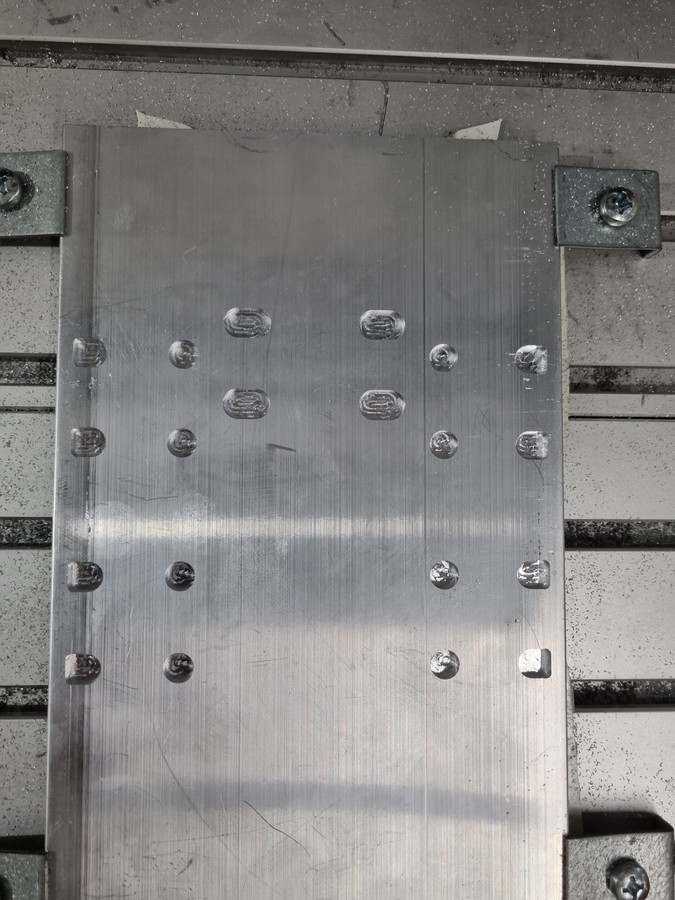

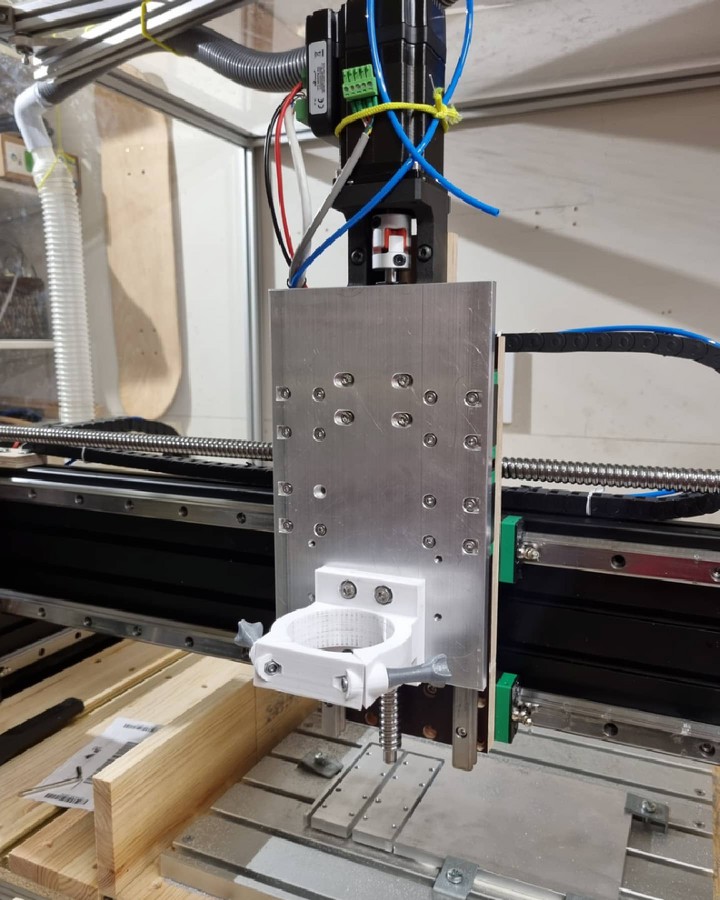

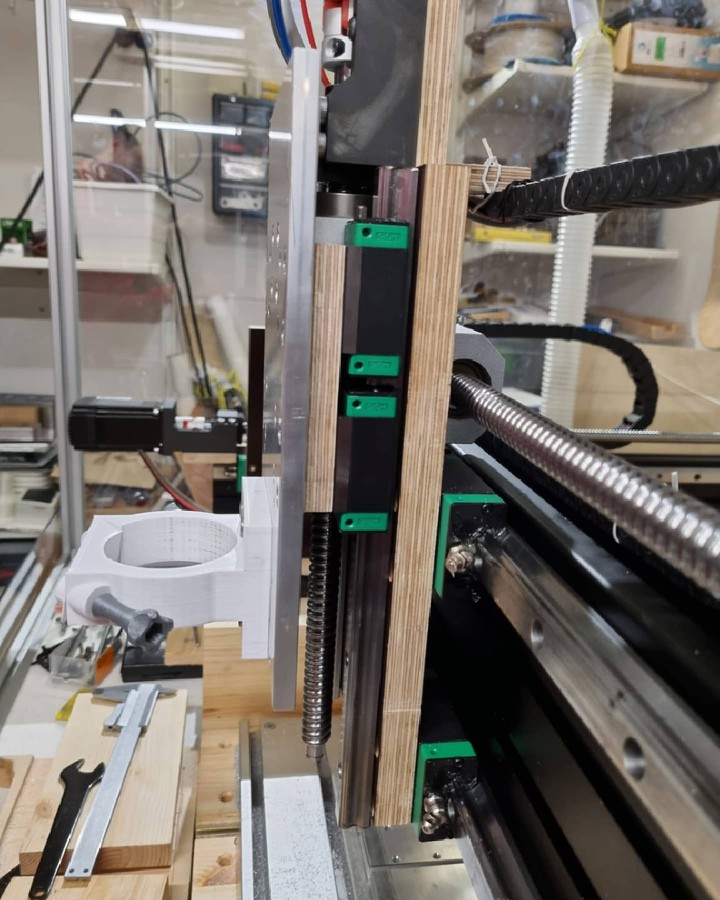

First off the Z axis plates are done. The Z plate and the spindle mount is currently being made. The Z plate was done without milling the edges of the plate since the aluminum bar was aligned very well. Holes for the HGH15 blocks were machined as well as for the ball screw nut hosing.

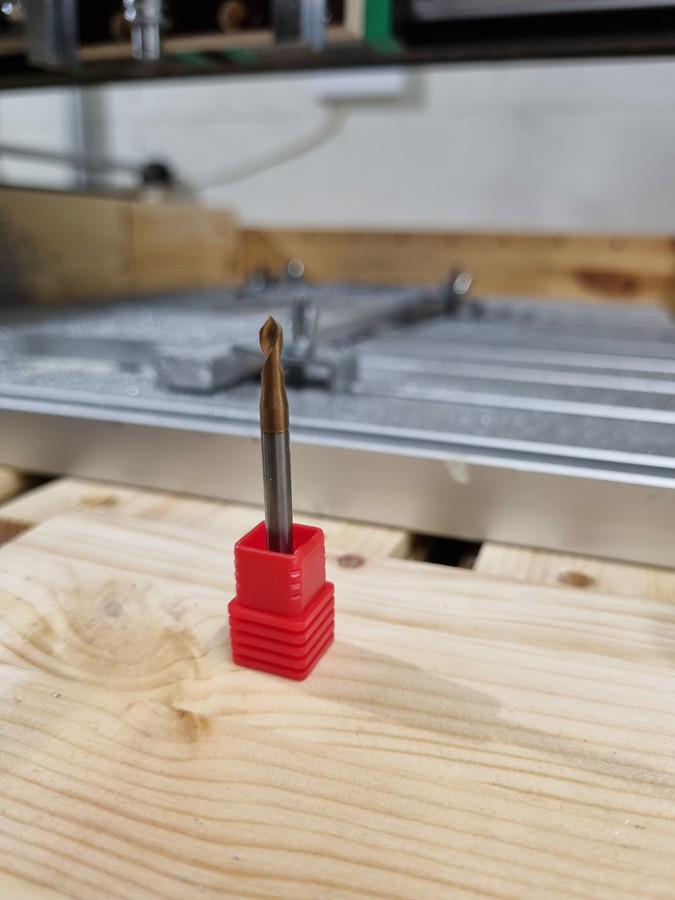

After this the edges were deburred using a 50 degree angle bit.

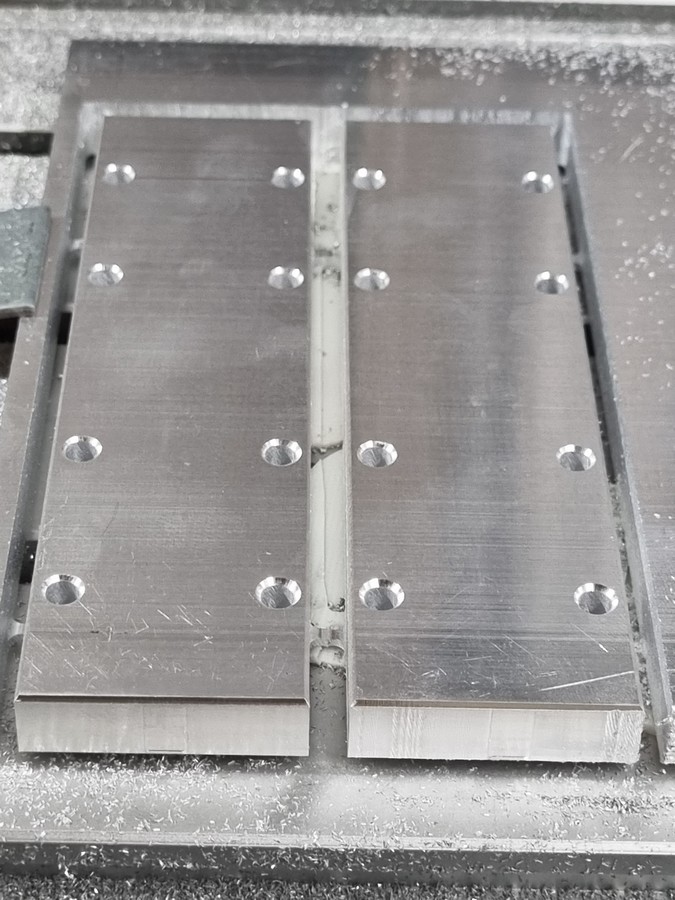

The Z plate needs some “spacers” between the HGH15 blocks and the plate in order to get the ball screw nut hosing on correct distance compared to the motor shaft center. The spacers is made of 10mm and 5mm aluminum plates.

The 5mm spacers are not done yet.

The whole Z setup can be assembled after the X carriage plate is machined but currently I have assembled the Z plate which made the Z quite rigid compared to the plywood setup…

The Z plate needed some threads for the spindle mount and also for a incoming project which i wont reveal yet 🙂

I used some cutting oil and a Makita hand drill to make the threads. The Threads came out very fine!

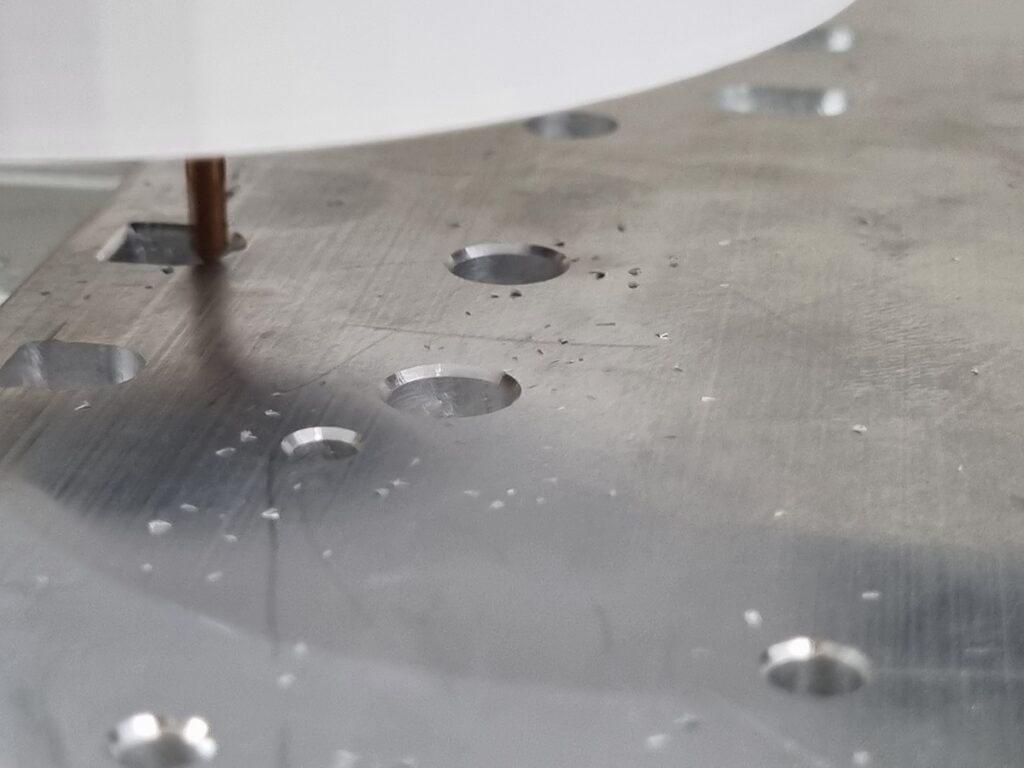

In addition to the Z plate and spacers I made also the spindle mount. The 3 holes in the center with pockets are for the mount clamp part. Also first pair of motor and ball screw bearing mount plates was milled from aluminum.