CNC Enclosure for laser and overall safety purposes

I still haven’t got the HM12 motor mounts. The are in a neighboring city but for some reason they were sent to west Finland and back to neighbor city (TNT packet) so I hope they will find me some day XD

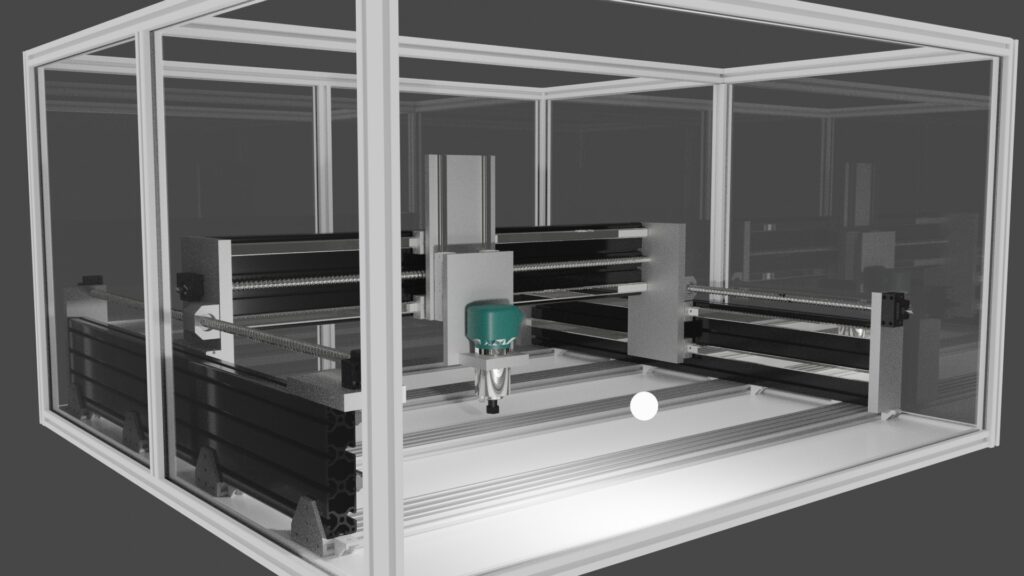

So the 3D design of the Enclosure was made again using the old CNC frame model and then took some grabcad models of some random 3030 profiles and modelled also a glass so that it looks a little more realistic.

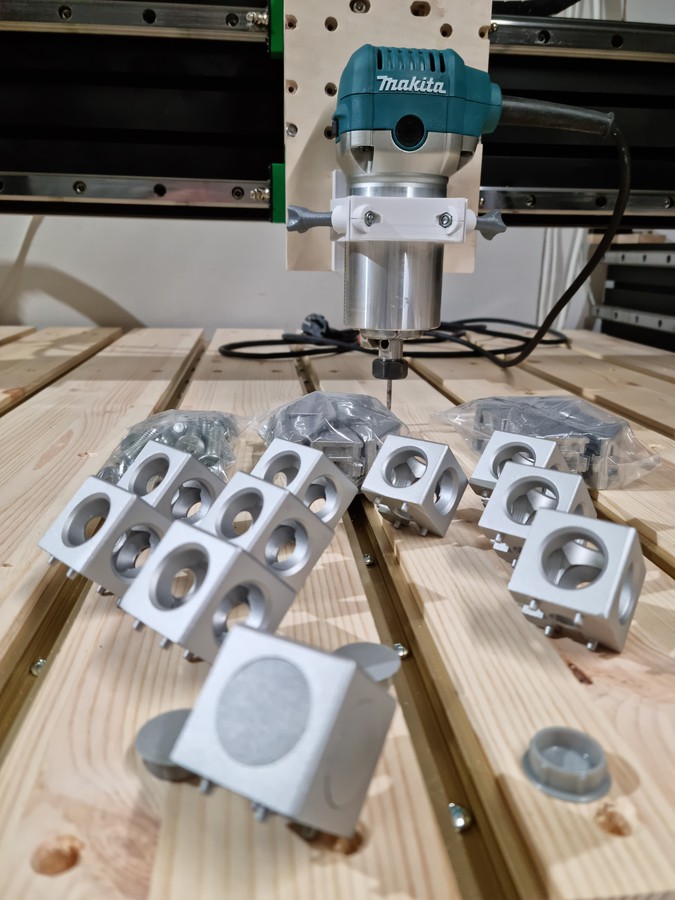

Today I received the Profiles and joining brackets for the enclosure from Easy Systems. They came well packed.

The parts can be found from Partners page. So I bought the 30x30mm BSB aluminum profiles sawed to 1000mm and 1300mm lengths. I need to saw them a little to get all fit up but I took a little excess if my original plan fails in something I couldn’t think of.

The 3030 90 cube connectors was really neat and fitted the profiles very well. They can be even capped using plastic aluminum look caps. The only problem I’m going to have with them is to make threads on in the profile center… That could have been done by Easy-systems when ordering the profiles but since I need to cut the profiles, I thought its better to try to do it my self… Hope I don’t ruin them 🙂

Next up the profiles need to be cut to proper length and it will hard I think but doable since they will “round up” the 1200x1200mm table edges and I need to fix them by screws to to the table.

This is not a fast project and needs to wait for the HM12 mounts before the Enclosure can be fully assembled. So fingers crossed -> need to wait for the mounts to arrive.