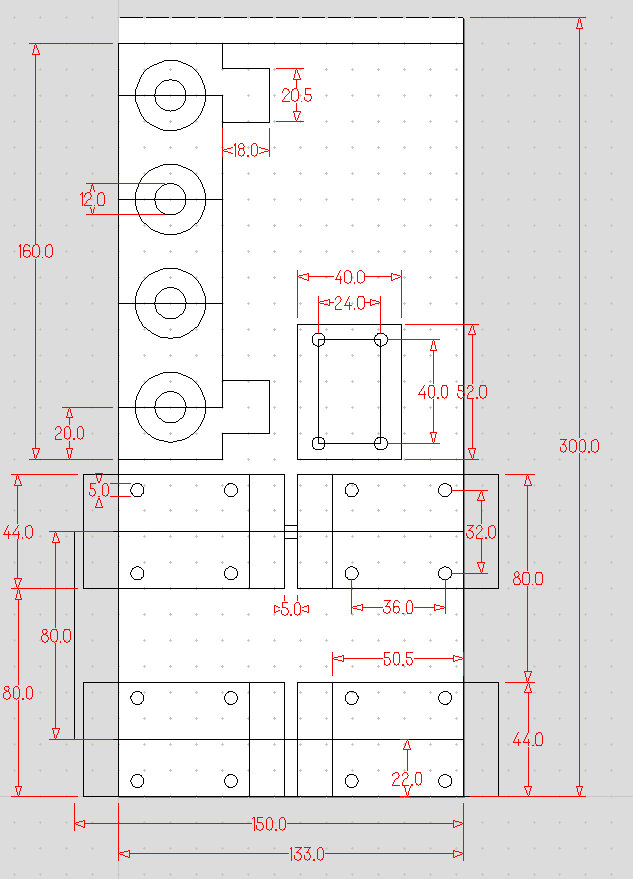

CNC Y-Axis gantry plate pre-prototype

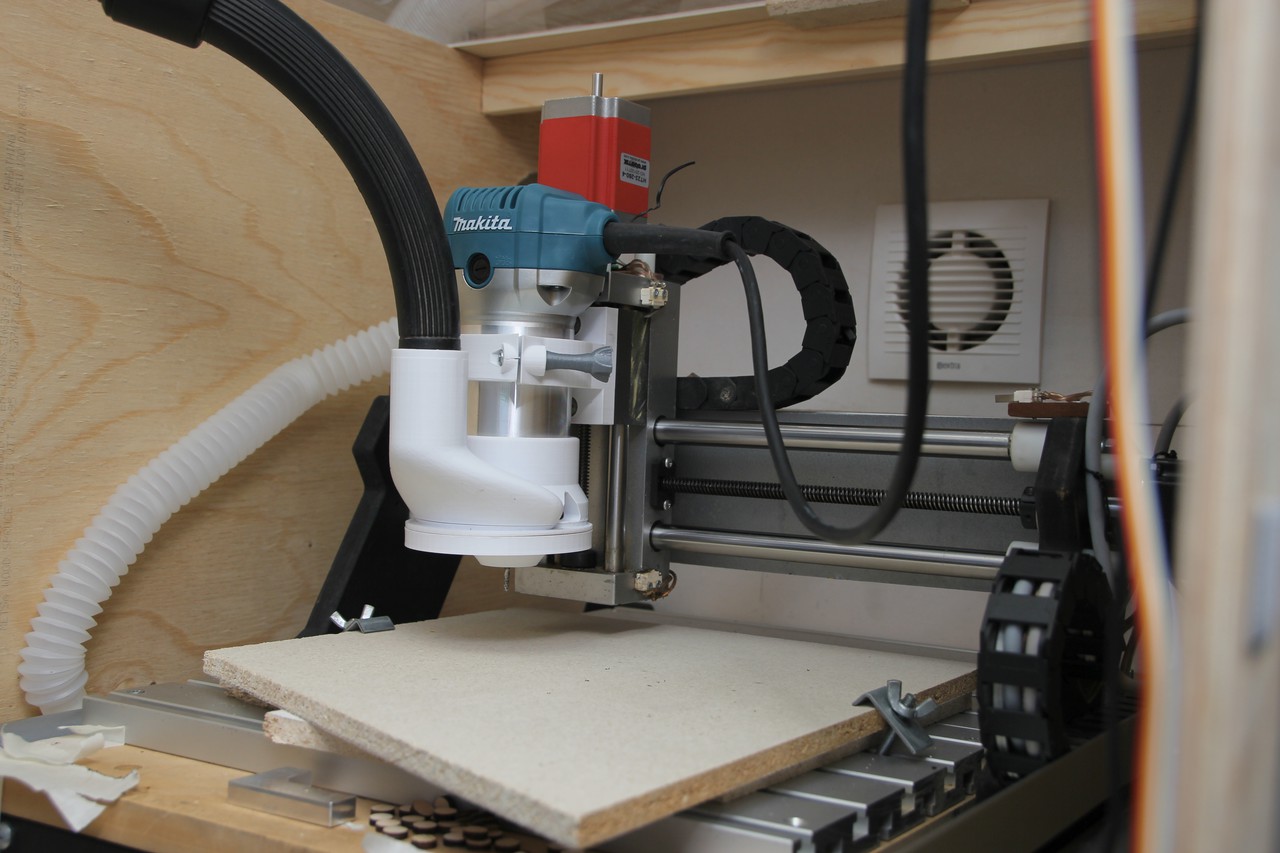

To be on safe side a prototype of the prototype gantry plate was routed using my old CNC machine on a 11mm thick wall chipboard. The idea was to check how much play there is to adjust the everything into square when assembled.

The routing bit is an ~3€ Toothed Diamond End Mill bought from Sorotec. The bit is good to work on plywood, chipboard and composite boards but probably only in slower speed. This was worked @ 600mm/min speed and approximately 2mm stepdown.

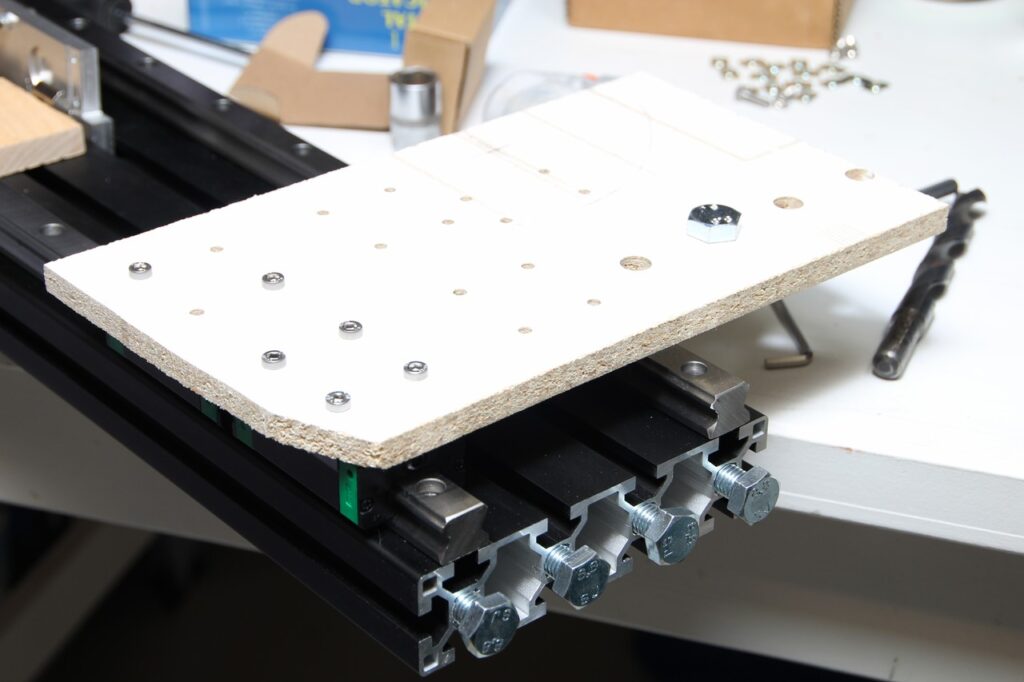

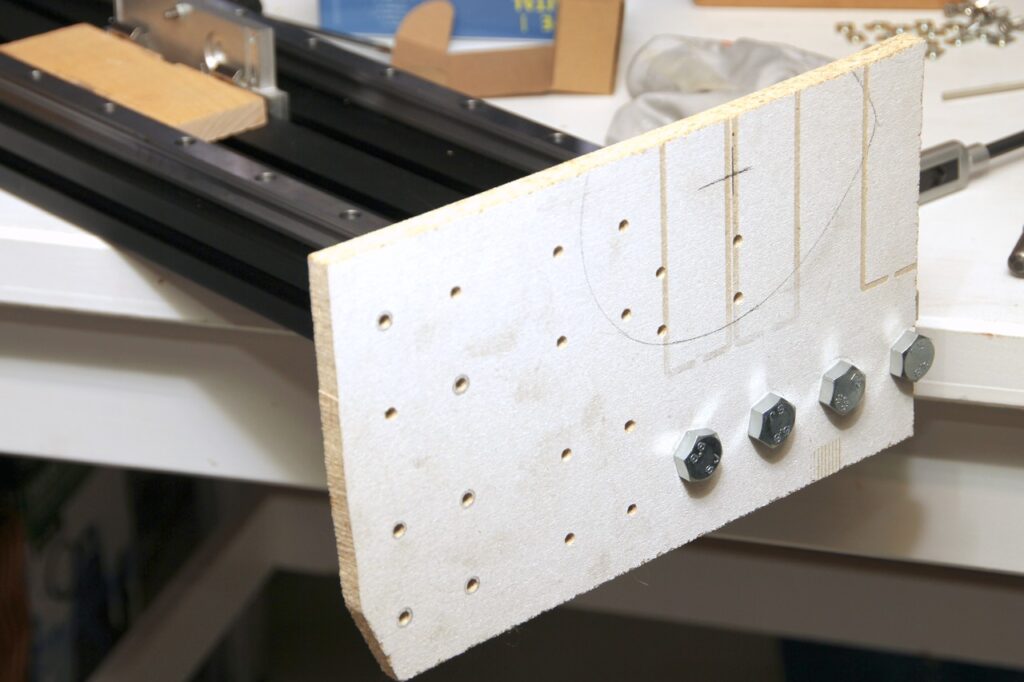

The work was finsihed and the HGH20CA blocks was screwed on the gantry plate. They have some millimeters play to it should be easy to set everything up and aligned with the main prototype.

One thing that needs enhancement is to get the bolts deeper into the gantry so some changes are made to the design. The pockets for the bolts are made so that its possible to tighten with a 19mm socket.

The next prototypes of the Y gantry will be made next week on film plywood.