Pressing images on T-Shirts using Heat press.

Pressing vinyl cutted heat transfers to a shirt is fairly simple process. You have a vector file, you mirror it (to get texts correct way after pressing) and send it to a vinyl cutter and then you pinch off excess vinyl that is not wanted on the final outcome. Then the heat transfer is laid on a shirt by measuring distances eg to neck, armpit seams and check the shirt bottom line is lined up. Then press for couple of seconds, peel of the heat transfer and press for 5 seconds and done.

For heat transfer vinyl I use Stahls Sportsfilm. It costs around 13€ per meter.

For digitalization i use a laser design software called Ligthburn which costs around 50€ but Inkscape (open source) is a really good alternative and is free.

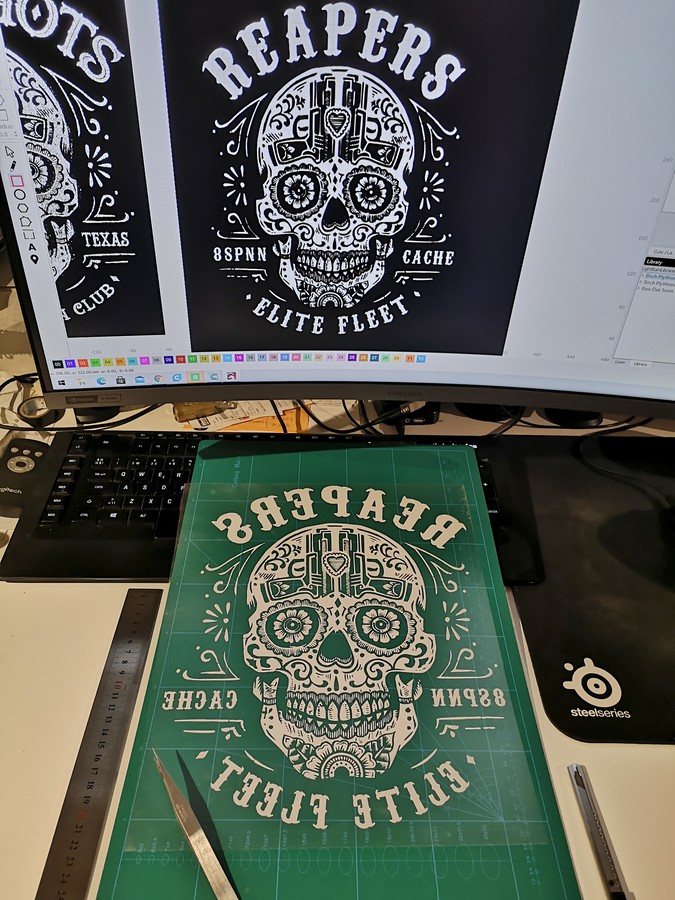

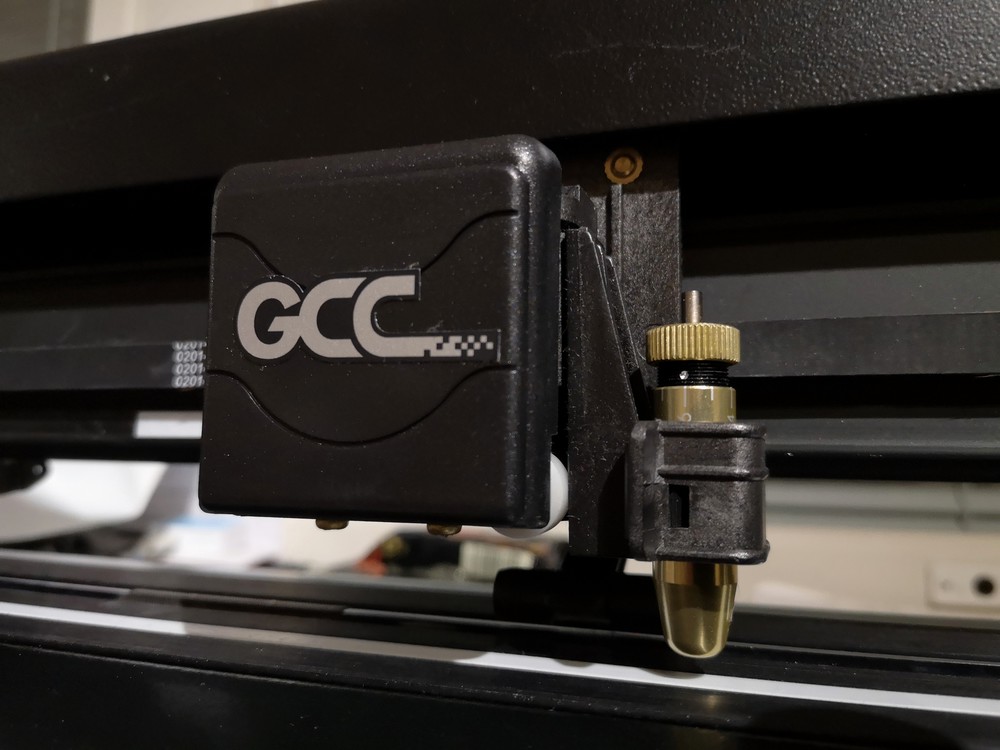

After digitalization and design changes I send export the vectors as .dxf file and import it into a program called greatcut2 for the vinyl cutter.

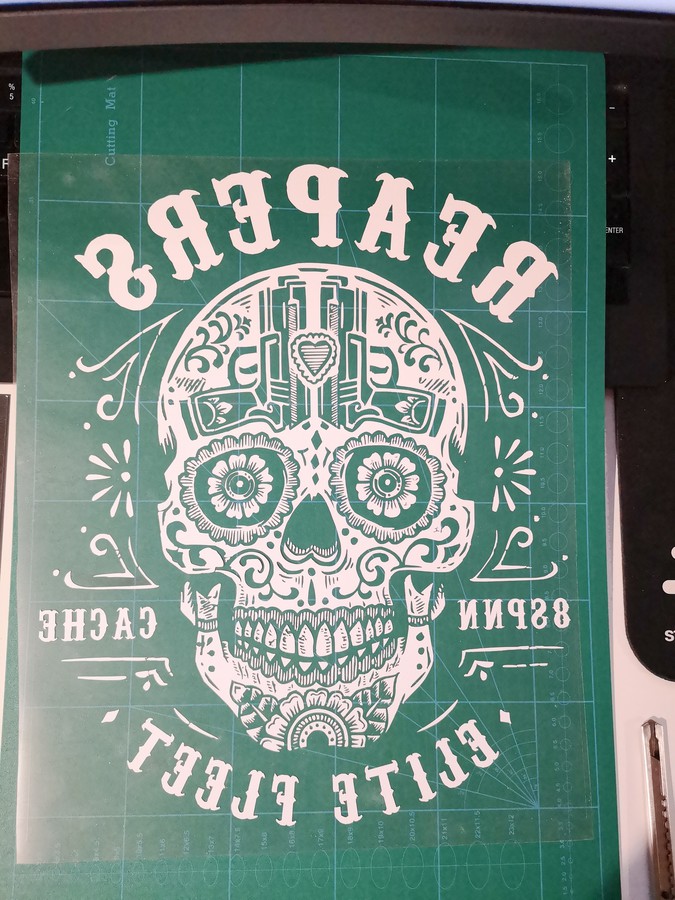

The weeding (after vinyl cutter is done cutting) of the image took approximately 1 hour which makes this kind of shirt making un-optimal for mass production but is a great way to make single custom designs on demand.

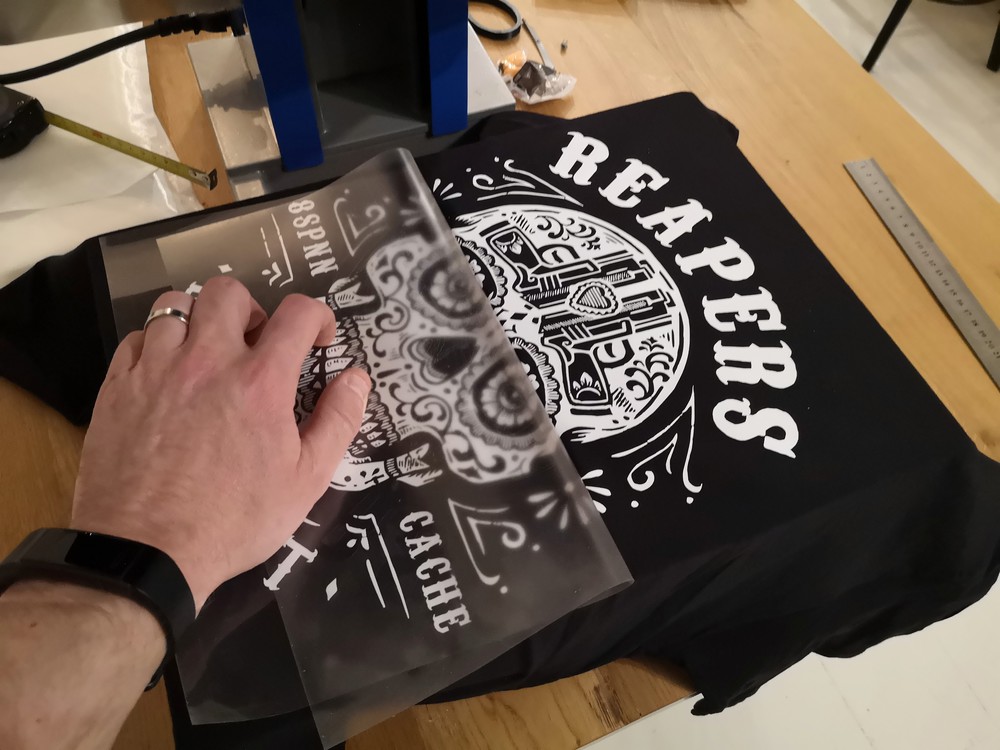

Here you can se the idea of mirroring the design. The glue on the heat transfer vinyl is on the other side of the heat transfer and thus the image is mirrored.

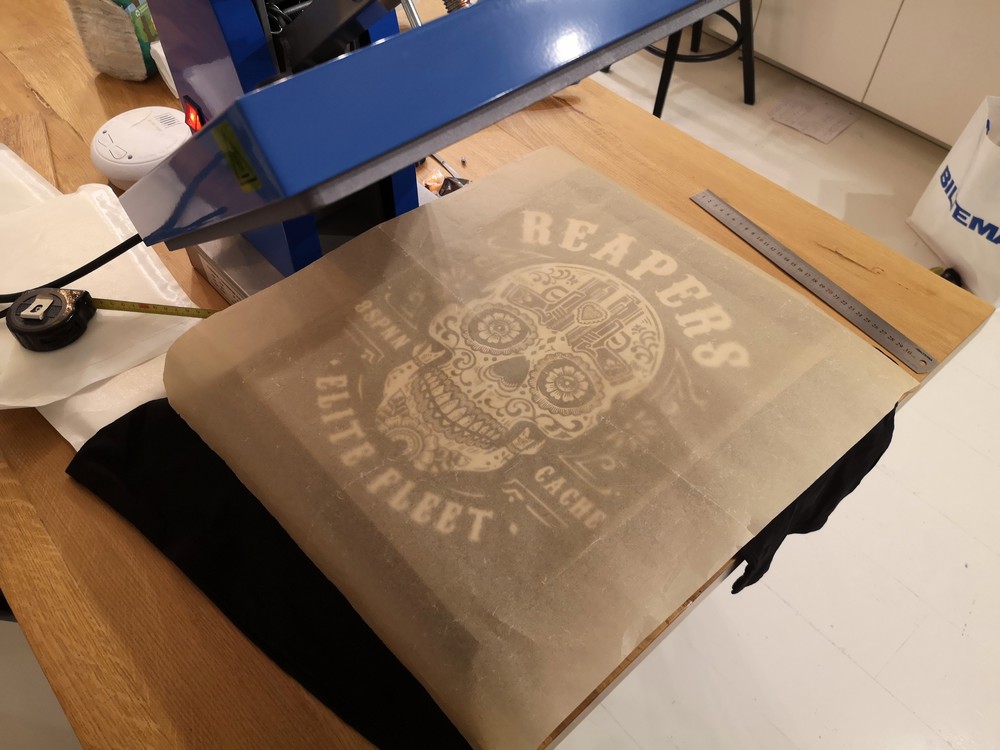

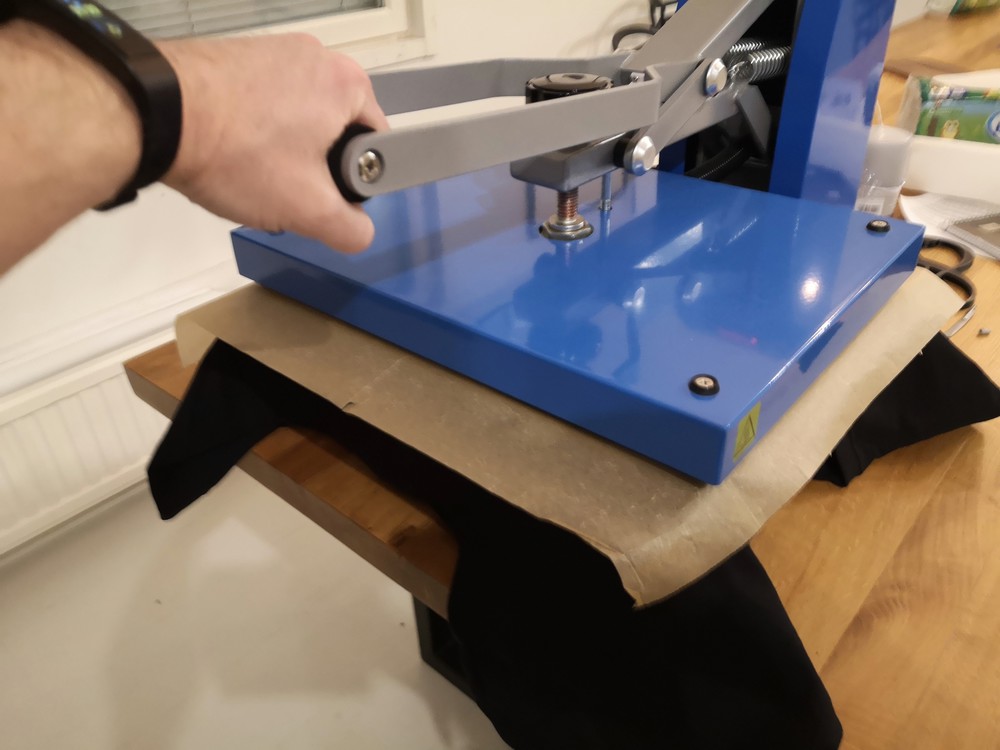

Before applying heat on the heat transfer I use a baking plate paper to reduce stains leaving on the hot heat press plate. The hot plate which is above the shirt in the image below (looks like a pizza stone 🙂 )

Apply heat for ~2 seconds and let it cool down 10-20 seconds.

Now peel the heat transfer off. The vinyl should stick on the shirt.

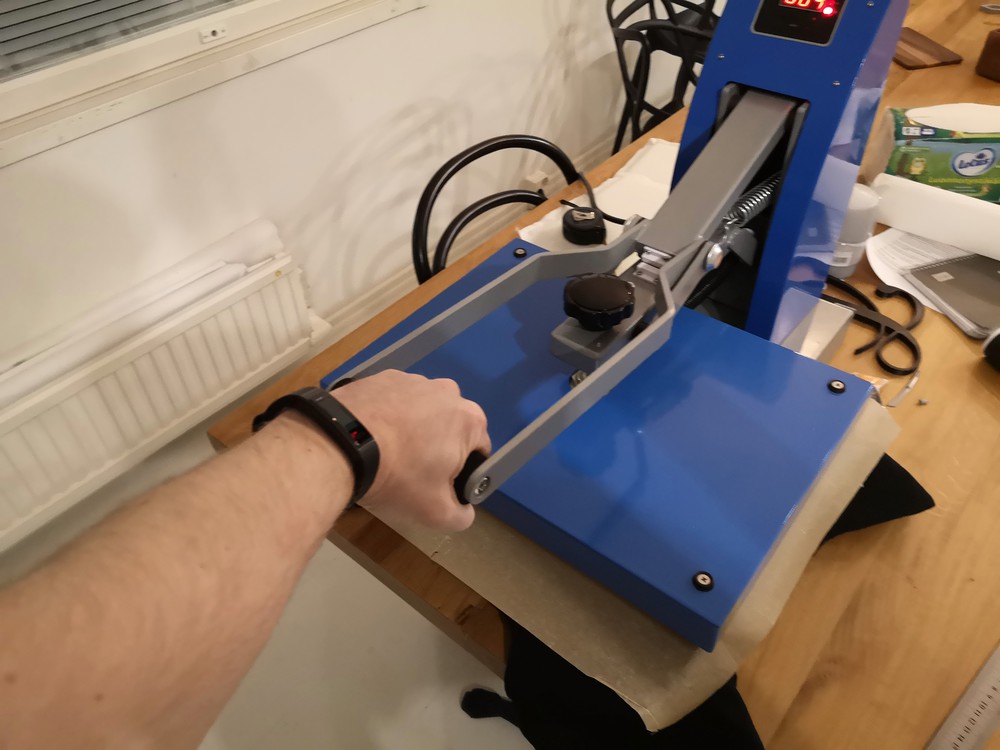

After hot peeling. Put the baking paper on the design and apply pressure for 5 seconds @ 150 degrees celcius.

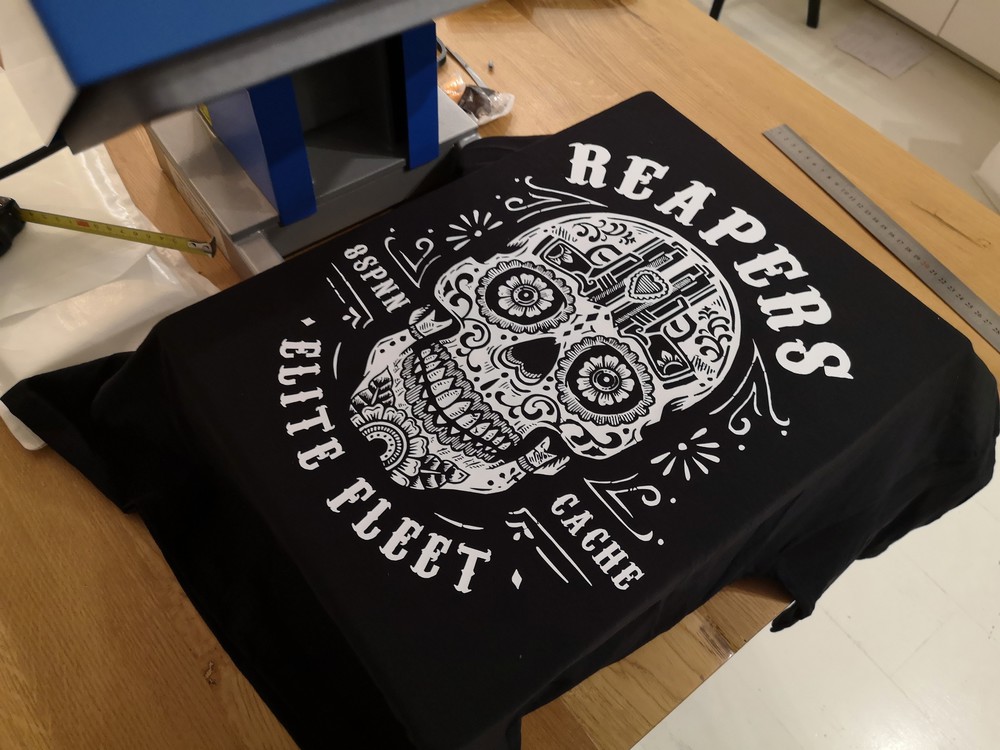

Now the shirt is done.

Conclusion is that the weeding is the most time consuming work when making this kind of shirts.

There are other methods like silk screen method which in my understanding is quite cheap and a better solution if you have a brand and want to mass produce it.

Other ways is to have a shirt printer to print the image straight to a shirt but that is way more expensive than the 2 first methods mentioned (heat transfer or silk screen method).