Cleaning of HGH15 and HGH20 blocks using IsoPropanol

While the T-nuts are on the journey from China to Finland (well they turned back to China but hope they will resend them soon…) I decided to clean the HGH blocks as i saw couple of videos on Youtube stating they should move better or more smoothly if they are cleaned. They stated there may be some “debris” or plastic chips or what so ever from the manufacturing process and that’s why it good to clean them before taken into use. The HGH15 blocks were also very stiff or moved very poorly on the HGR15 rail so that was also a driver to try to get them better by cleaning.

Before i took the HGH blocks into the “wash” i wanted to put most of the parts that im going to use to build the CNC machine. 2080 v-slot profiles and related bolts, brackets etc from Nettiverstas, 20 and 10mm thick Aluminum bars from Al-Men, 40160 Aluminum profiles from Ratrig with related brackets and M8 T-nuts, HGH & HGR 20 and 15 blocks, 1605 ball screws, 48VDC 1500W power supply From AliExpress.

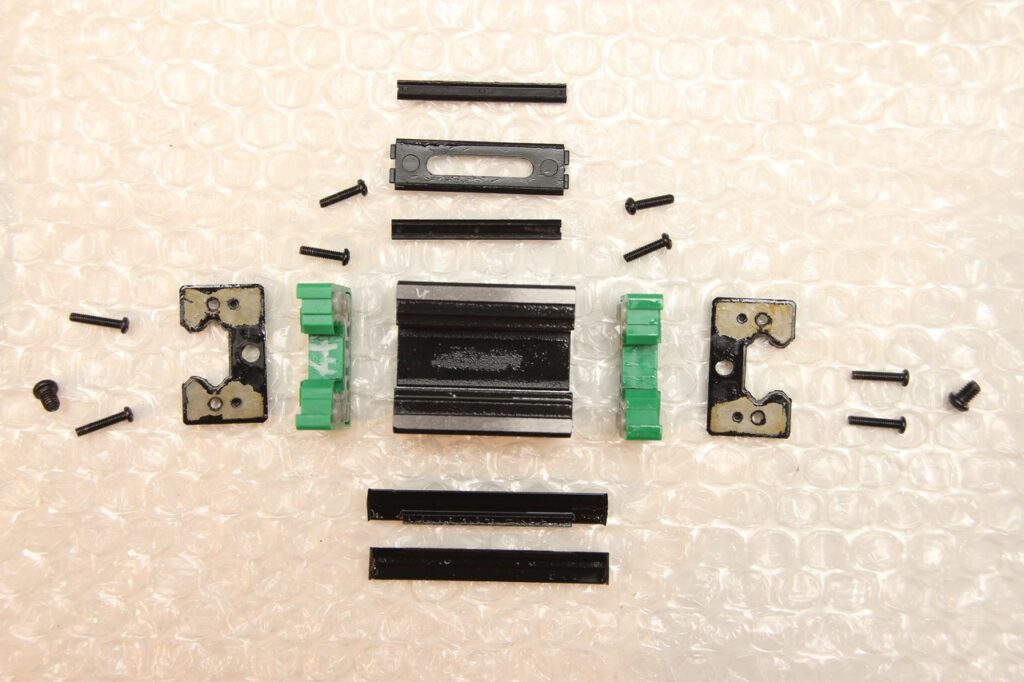

Well anyway it was time to take the blocks and disassemble them. First off the HGH15 blocks.

After assembling the HGH15 I decided that its going to be to big task to take all the HGH20 blocks apart and clean so i cleaned the HGH20 blocks just by unscrewing the grease bolts out and then I sprayed Iso-Propanol into the grease insert and also the visible balls underneath the block. I sprayed, then I moved the balls and sprayed again and did this several time to get most of the manufacturing left overs away from the ball mechanism.

If you are going to disassemble or clean your blocks, be very careful not to loose any balls since they come out quite easily after the plastic holders are taken out.

And at last after several hours they were ready to an vaporize the left over iso-propanols away.

The Iso-propanol was bought from a local store called Motonet.

After cleaning process the HGH15 blocks were still quite stiff but I decided to give them a go although they are stiff. The HGH20 were better from the beginning and thus the smoothness of them was not noticeable. All in all, Cleaning process was probably good to do since there was some steel chips in floating in the iso-propanol and other dirt also (not in large quantities but some…)

I’m not going to describe how to grease the block bearings since i’m in the learning process and i have difficulties to get the grease pumped inside the block, all the grease just squeezes around “over the edges” and seems not to go into the block where it should go… But there will be a post as soon as i know whats the problem 😂