Ball screw shaft offset measurement using Dial indicator

Since the ball screw wobbles quite much, some tuning to the bearing blocks was made and after around 30minutes tuning the shaft offset was measured to around 50-60µm (micrometers).

This can probably be reduced further using HM12 motor mount which actually was ordered since the printed motor mounts were too flexible.

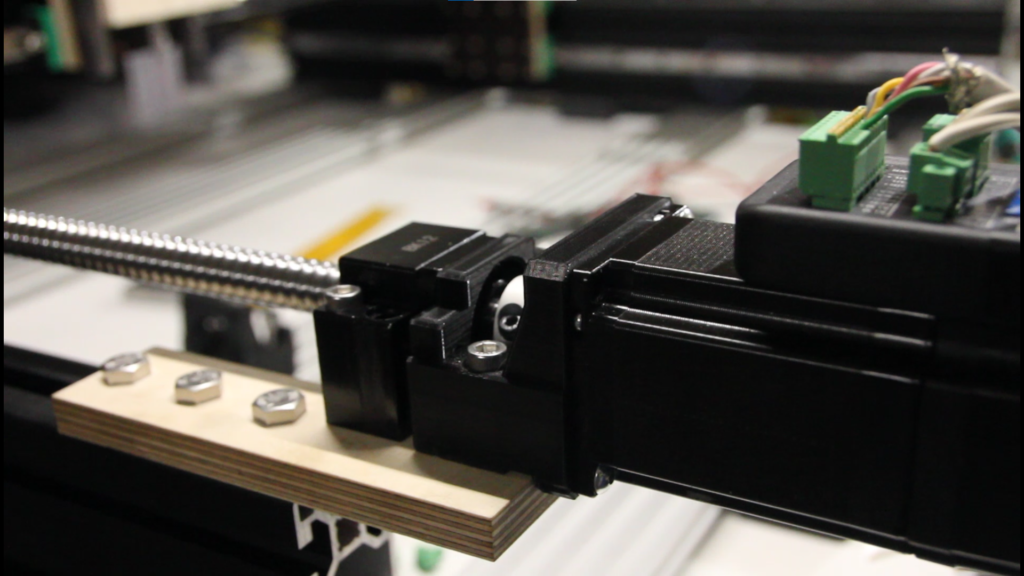

The nut hosing and the ball screw nut was also tried to be adjusted as precise as possible by adjusting the BK and BF bearing blocks that are on each end of the ball screw. (BK12 at motor side and BF12 as end bearing on opposite end).

The eccentric ball screw wobble effect may not get that good with these plywood prototype plates but i want them to be as precise as possible since this plywood plate prototype version is used to machine the aluminum plates. I believe the aluminum plates will make it much more rigid in the end but this showed me again one thing that must be changed in the aluminum plates -> There mnay need to be X direction adjustment for each bearing block also.