HM12 Nema23 Size Motor Mounts Arrived 😁

INTRO

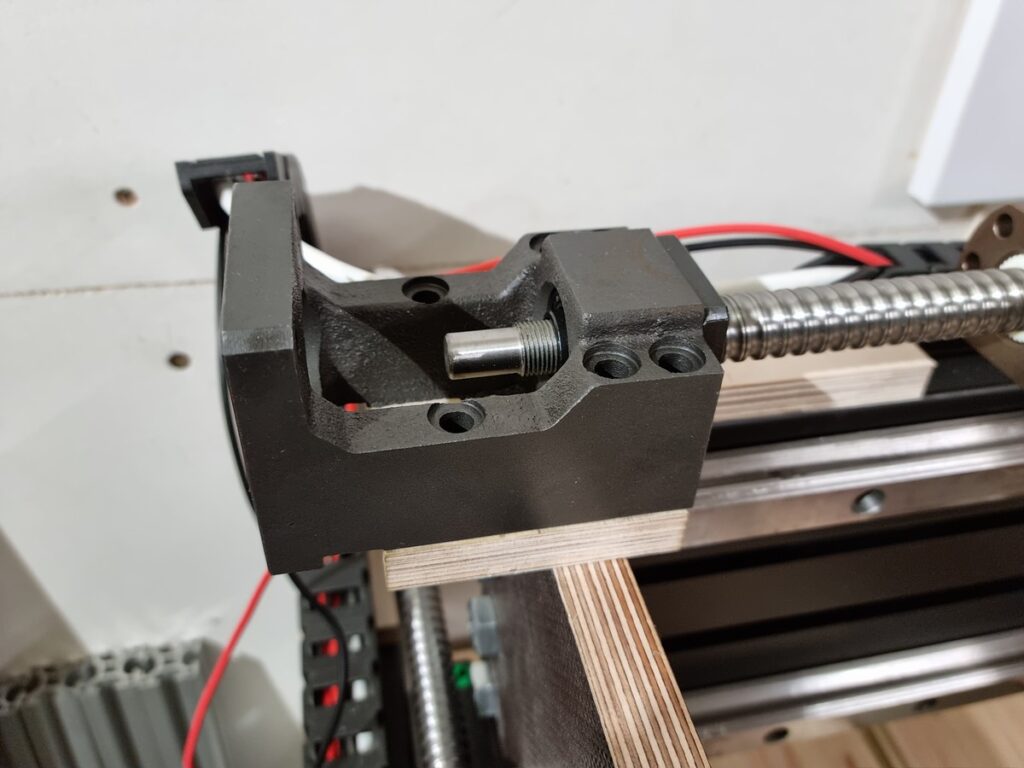

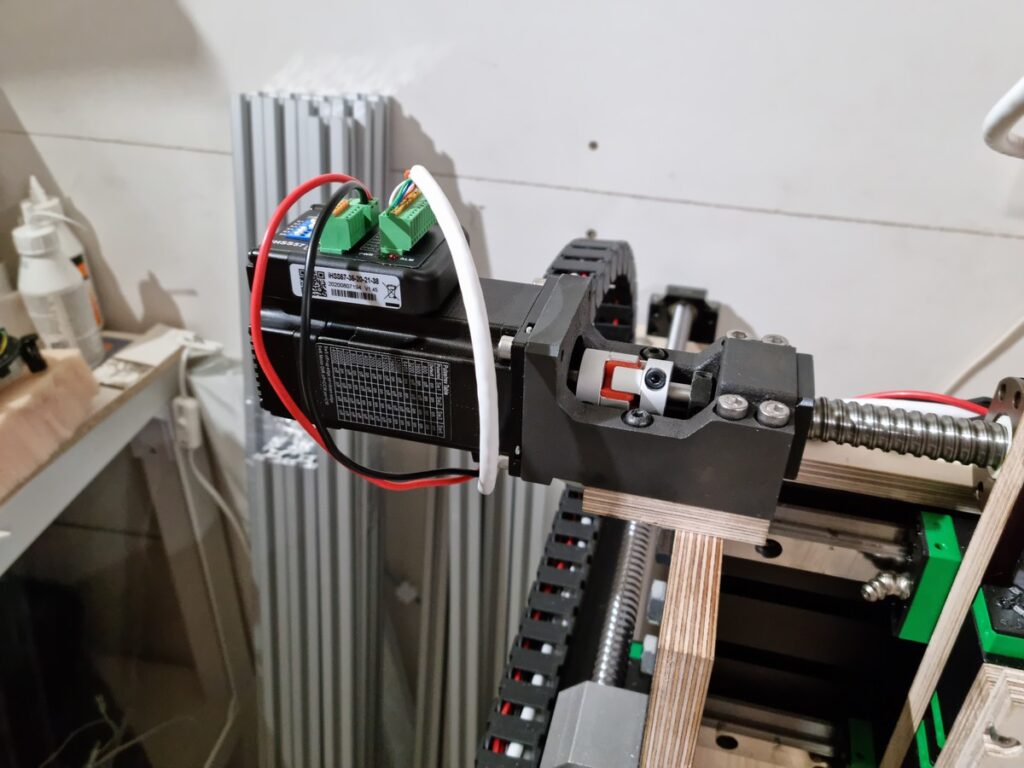

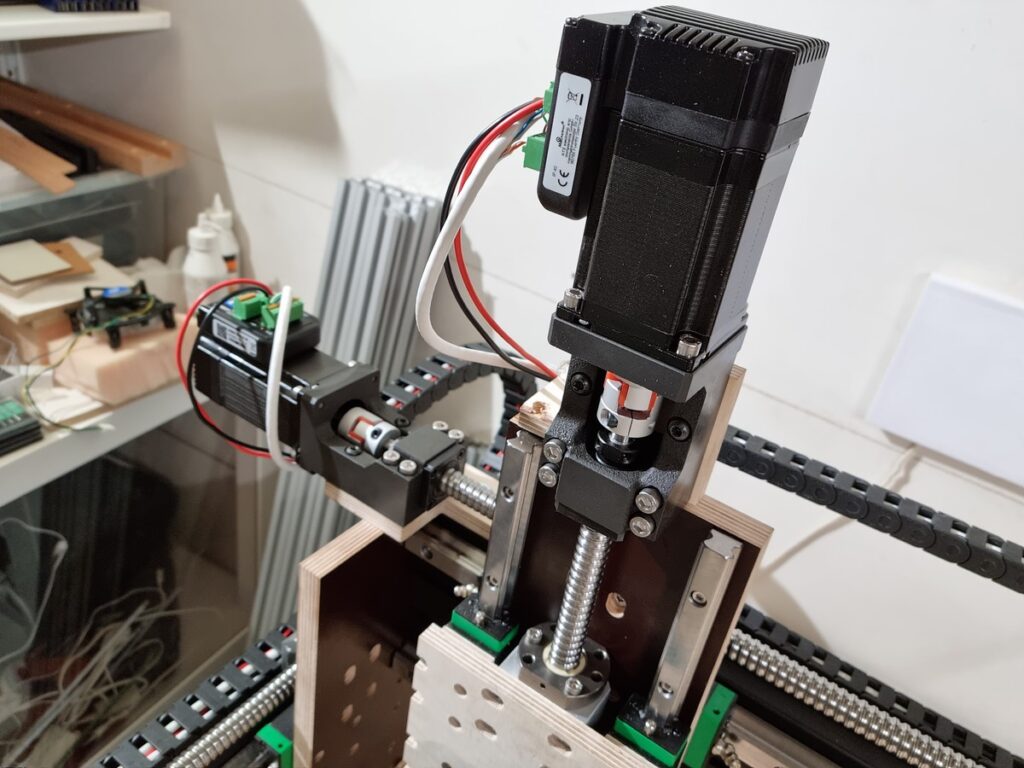

Finally i got the HM12 motor mounts and I was able to install them on my machine straight away. The Mounts did not fit 1:1 to my old endplate holes but I managed to to use BK12 block holes 1:1 and the other 2 holes was around 1/3 visible from mount holes so there I used wood screws.

HOW IT WORKS

Currently I have nothing bad to say about the mounts. The whole ball screw assembly is still a little too wobbly and I can run my machine at max 5000mm/min. It starts to wobble quite fast. For X and Y ball screw I measured around 0.3mm wobble offset at center of the screws using a dial indicator. At 10000mm/min speeds the wobble introduces vibration which was felt on the router bit and that’s not a good thing since the CNC is planned to use also laser.

ISSUES & CONSIDERATIONS WHEN BUYNG BALL SCREWS

When buying the ball screws the manufacturing method should be chosen correctly. There are different classes from 1 to 7 I think for the ball screws where class 1 is the best with minimal variances in the ball screws. Then there is manufacturing type -> Rolled and Ground. Rolled means the ball screw threads are squeezed in form using heavy duty form wheels to crush the thread shape on the ball screw. The Ground ball screw basically means it grinded.

Rolled is obviously cheaper and 1000mm screws can be bough for ~50$ while a ground ball screw was even hard to find over 800mm long and cost is over x5 more expensive. If you want a low budget machine it could be good to buy a longer pitch screw. My screw is with 5mm pitch. This means to move fast the rod needs to rotate very fast. But there are ball screws up to 1620 which means 16 diameter and 20mm pitch. In this case the torque is decrease and needs more power from motors compared to 5mm pitch but in other hand motors don’t need to rotate that fast to achieve same speeds compared to 5mm pitch so its a trade of you need to think. But in other words a higher pitch screw could decrease the wobble and could be a better option. I may buy a 10 or 20mm pitched screw for X axis but that’s only after all parts are out of solid material and not plywood as they currently are.

Here are a couple of more images of the HM12 mount setup